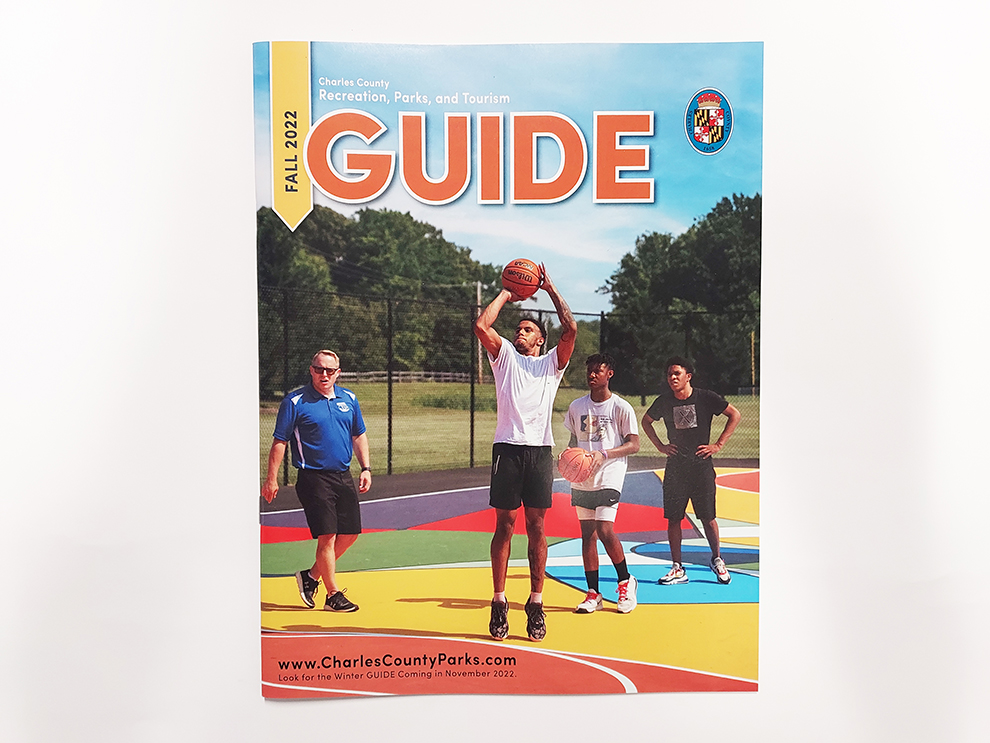

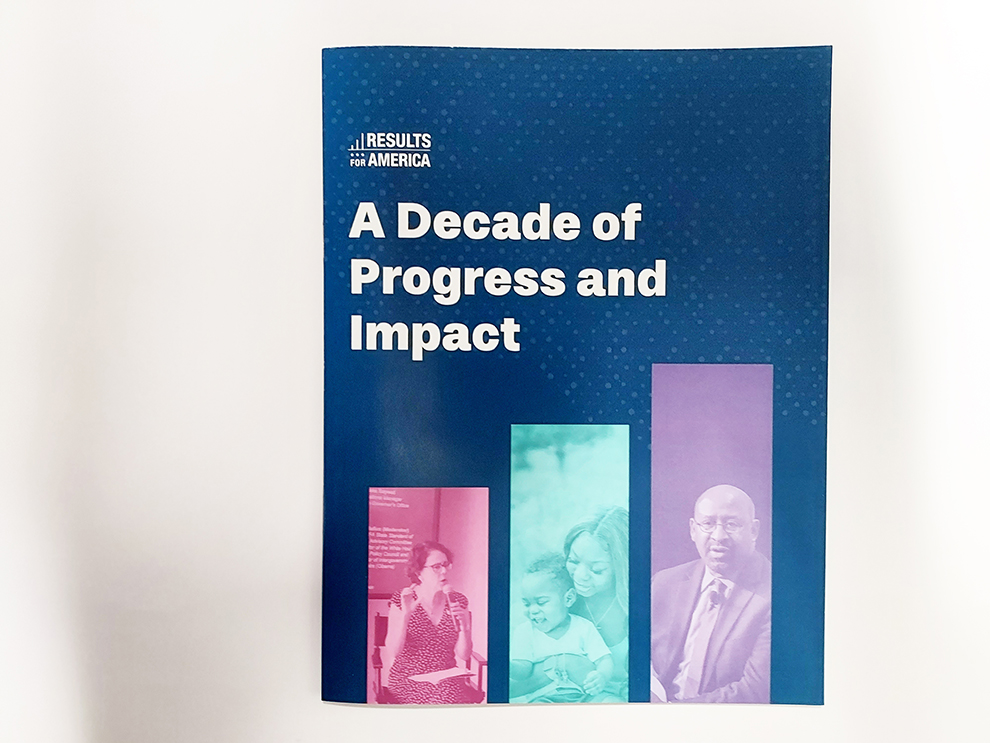

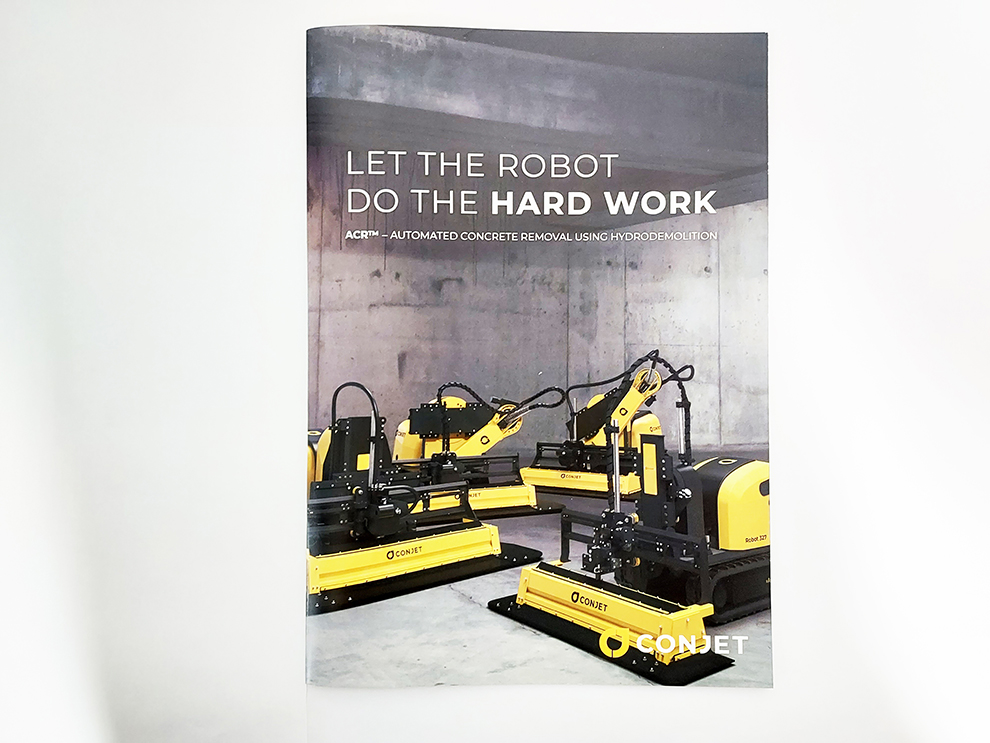

Booklets serve as a powerful marketing medium for businesses of all types and sizes. They present an engaging and informative platform to highlight your offerings or services in an aesthetically pleasing manner. Booklets are ideal for presenting comprehensive information about your products, services, or corporate history. They can function as product catalogs, event schedules, or instruction manuals. Moreover, booklets can effectively enhance your business promotion and brand visibility.

Customized booklets rank among the most effective marketing materials that your corporation or organization can utilize to engage with prospective consumers. They are compelling and informative promotional tools that can assist you in showcasing your goods and services, offering valuable information, or simply narrating your brand narrative.

At Heritage Signs & Displays, we understand the impact that high-quality printing can have on your business, and we’re here to help. We offer a wide range of custom booklet printing options, including laminated covers, spot foil stamping, die cutting, and blind embossing. Our covers come in dozens of different textures, gloss levels, finishes, and thicknesses to help you create a truly unique product.

James was Awesome, he provided great customer service and insured that the graphics would be up in time to meet our tight deadline. The whole team was Great! I can't wait to do business with them again in the near future! -

Booklets provide a plethora of applications and uses, making them incredibly adaptable. You can tailor the size, shape, and structure of your booklets to meet your branding requirements and objectives. For instance, a travel firm can design an entertaining, foldable booklet that highlights various destinations and tour packages. Conversely, a software company can produce a technical guide that outlines the features and advantages of their software products. Irrespective of your sector, booklets can assist you in delivering your message in a manner that is both informative and visually captivating.

Custom booklet printing can be employed to create a striking brand image and fortify brand identity. Booklets can be fashioned to align with your brand guidelines, integrating your logo, colors, fonts, and pictures. This uniformity across all your promotional materials boosts brand recognition and generates a robust impression of your enterprise. Moreover, customized booklets enable you to infuse your brand personality by incorporating unique elements like illustrations, quotes, and endorsements.

One of the key benefits of custom booklet printing is its cost-effectiveness. Printed marketing materials are available in various budgets and eliminate the continual cost of digital marketing. It's always a preferable choice to print a few hundred brochures or booklets that remain in circulation for an extended period, instead of investing in a digital ad campaign that can get lost amidst numerous competitors. With the right combination of messaging and design, a well-conceived booklet can create a significant impact without straining your budget.

Booklets are incredibly handy for distribution at events, conferences, and trade fairs. They are lightweight, portable, and simple to distribute. Compared to other promotional materials, booklets have a longer lifespan and can be retained by recipients for future reference. Booklets can be used on a one-to-one basis where the exchange of information is paramount.

One of the most significant advantages of booklets is their tangibility. Holding something physical makes it more real. The texture, weight, glossiness, and ink quality of a booklet can leave a lasting impression on the recipient. Booklets are more than just pieces of paper, they are a physical embodiment of your brand that elevates your brand image and leaves a lasting impression.

If you're in the market for booklet printing services, it's important to choose a company that will provide the quality and customer service you deserve. At Heritage Signs & Displays, we are a veteran-owned booklet printing company that you can trust for all your printing needs. With over 40 years of experience, we have built a reputation for being progressive in our ability to innovate and evolve with the ever-changing needs of our clients in Washington, DC. Our expert team has won hundreds of print quality awards at regional, national, and international competitions. We have the printing and binding technology to provide these products at affordable rates, and we offer direct mailing services to help you get your booklets to your customer list with ease. We have earned hundreds of 5-star reviews from our satisfied clients in the process.

Our state-of-the-art printing technology and digital color printing provide fast and affordable results that guarantee a match of your brand colors and a vibrant, crisp presentation of your logo. When you first reach out to Heritage Signs & Displays, our printing experts will gather more information about your booklet printing request. Based on the information we gather from your team, we’ll prepare a proposal that establishes the cost and timeline for proof and production. We’ll create a printed and bound sample for your review and approval, using specialized printing technology and top-quality materials that match your final printed booklet. After you approve the proof, we’ll contact you to arrange the pickup or delivery of your booklets.

There are several types of paper that can be used for booklet printing, each with its own unique characteristics and advantages. Some common types include:

Glossy paper - This type of paper has a shiny finish and is commonly used for printing photographs and images due to its ability to make colors appear more vibrant.

Matte paper - In contrast to glossy paper, matte paper has a non-shiny finish and is often preferred for its professional and elegant look.

Recycled paper - This type of paper is made from recycled materials, making it a more environmentally friendly option. It may have a slightly different texture compared to other papers.

Coated paper - Coated paper has a layer of coating applied to the surface, which gives it a smoother finish and makes it more resistant to smudges and fingerprints.

Uncoated paper - Unlike coated paper, uncoated paper has no coating applied to the surface, making it more absorbent and better suited for printing text-based booklets.

Cardstock - This type of paper is thicker and sturdier than regular printer paper, making it suitable for booklet covers or high-quality images.

Specialty paper - There are also a variety of specialty papers available for booklet printing, such as textured paper, metallic paper, and colored paper. These can add a unique touch to your booklets and make them stand out.

Saddle Stitching: This is a highly sought-after and cost-efficient method for booklet binding. It involves folding the pages in half and stapling them along the crease to form a booklet. This technique is optimal for booklets with fewer pages, as it can only hold up to 64 pages.

Perfect Binding: This technique involves adhering the spine of the booklet to a wraparound cover, creating a neat and professional appearance. It's suitable for thicker booklets that contain more pages (up to 200). Perfect binding is typically utilized for magazines, catalogs, and novels.

Coil Binding: Also referred to as spiral binding, this technique uses a plastic coil inserted through holes punched along the booklet's spine. It enables the booklet to lay flat when opened and can hold a larger number of pages (up to 300 pages). However, it might not be ideal for booklets with numerous images or graphics, as they could become entangled in the coils.

Wire-O Binding: This method is similar to coil binding but uses a double-loop wire instead of a plastic coil. It provides a sleek and professional appearance and can hold a larger number of pages (up to 400 pages). Wire-O binding is frequently used for manuals, workbooks, and reports.

Yes! We include shipping costs in the final invoice for your approval. Or if you are local and wish to pick up your booklets from our production facility, you may do so and save on shipping costs.

We understand that timing is crucial, which is why we aim to have most digitally printed booklets delivered within three-to-five working days from final proof approval. For offset printed publications, it will typically take 8 to 10 working days to complete in our normal production schedule. We also offer expedited printing and shipping solutions to meet your specific timeline needs.

Several elements can influence the production time of your booklet. The complexity of your desired booklet could affect the duration. For instance, a basic booklet containing only images and text might be quicker to produce than a more complex one with numerous pages, folds, and unique finishes. The binding technique you select for your booklet is another critical consideration. Booklets bound with staples are usually quicker to print and bind than those with perfect or spiral bindings because the stapling process is simpler, while perfect and spiral bindings necessitate extra steps like gluing or hole-punching.

In conclusion, choosing a local booklet printing company that prioritizes quality and service is important for making a great first impression. With Heritage Signs & Displays, you can stand out from the crowd with high-quality, custom-printed booklets that reflect positively on your brand. Contact us today at (202) 609-9761 to learn more about our custom booklet printing options and direct mail services, or Get a Quote for free on our website.